Major Construction Features

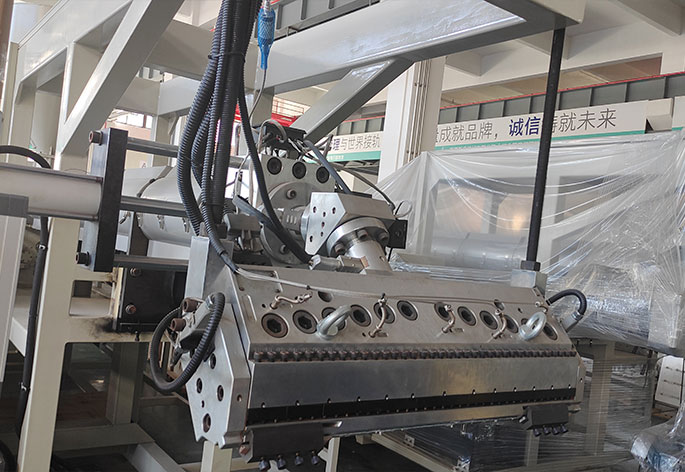

- The sheet extrusion unit is a combination of extruderthree roll calenders,haul-off unit,winderlincluding waste sheet winder and electric control cabinet.

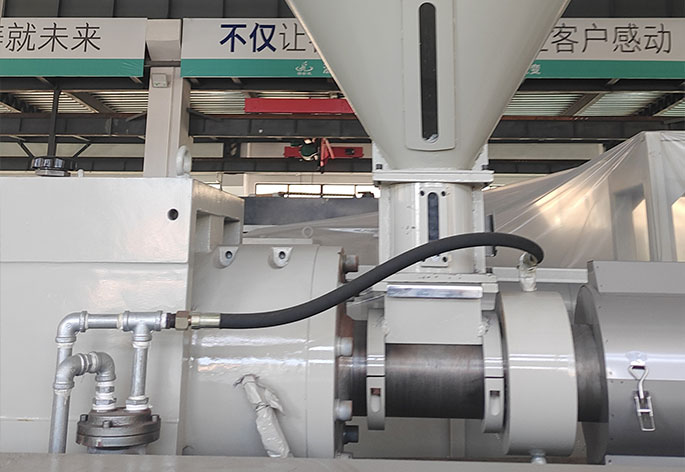

- The main parts, such as screw, barrel, screen exchanger, T-die adopt superior alloy steel(38 CrMoAlA) with high hardness strong corrosions resistance and long operating life after nitrogen treatment.

- The screw adopts big L/D ratio,equal plasticization and high plasticizing capability.

- Non-stop fast screen changer with double-sieve, controlled by hydraulic device, the operation is convenient and improve the production efficiency.

- The calendar.haul off unit and winder adopt integration design,fine appearance,convenient and improve the production eficiency.

- The machine frame adopt square steel, to make sure the machine works stably in high speed. The motor is connected with gear box directly, improve production efficiency and lower energy consumption.

- Note: Special specification and configuration of products can be designed according to customer' s demand.

Main Technical Parameters

| Model |

SY-PC-90-A |

SY-PC-110-A |

SY-PC-120-A |

SY-PC-140-B |

| Raw Materia |

PPPS, HIPS, PE |

PPPS, HIPS, PE |

PPPS, HIPS, PE |

PPPS |

| Sheet Thickness |

0.3-2mm |

0.3-2mm |

0.3-2mm |

0.3-2mm |

| Layer |

1 |

1 |

1 |

1 |

| Extrusion Capacity |

100kg/h |

200kg/h |

250kg/h |

250kg/h |

| Screw Dia. |

90mm |

110mm |

120mm |

120mm |

| L/D Ratio |

33:1 |

33:1 |

35:1 |

35:1 |

| Roller Dia. |

Φ350mm×3 |

Φ350mm×3 |

Φ400mm×3 |

Φ400mm×3 |

| Main Motor Power |

37kw |

55kw |

110kw |

110kw |

| Overall Power |

90kw |

120kw |

160kw |

160kw |

| Weight |

5.5T |

7T |

8T |

8T |