Max.Forming Area: 1100 / 850

Max.Forming Height And Depth: 145/125

Max.sheet width: 1130

Main construction features:

1. European design, fully functional, suitable for diversified production lines, safe and efficient, energy-saving and hygienic

2. Unwinding station electric lifting, double roll frame, a single person can load the maximum 1T coil material

3. Humanized HMl, and the system has a remote on-line function

4. Fast and accurate temperature control system (error ± 1 degree), with a hot stove to detect dropout and gas source low pressure protection system

5. Intelligent operation, the whole machine with formula storage, automatic adjustment without stopping the machine

6. Can share the mold with most famous brands at home and abroad, with the existing production line.

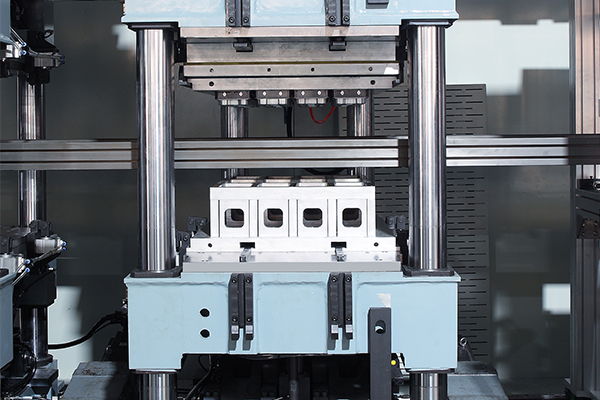

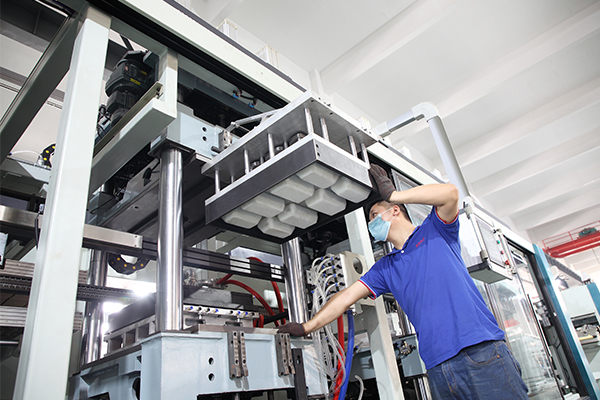

7. Quick mold change system, which can facilitate fast, accurate and safe mold change and reduce downtime.

8. Under any molding program, the clamping frame and insertion and extraction auxiliary functions can be used separately or simultaneously, greatly simplifying the mold structure.

9. Materials with strong shrinkage can be cut by single-station in-mold molding, which ensures the precision of edge cutting.

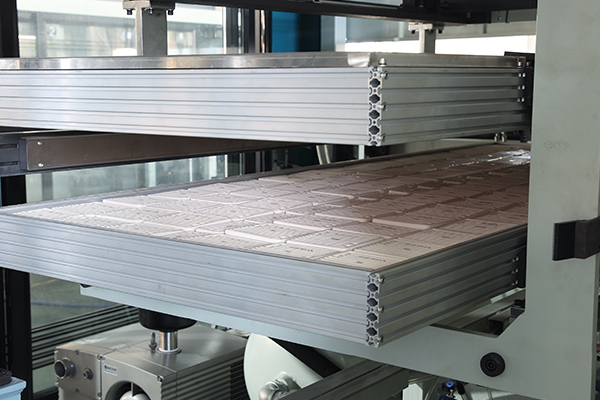

10. High-precision molding and cutting technology realizes high-speed control and low-wear molding and cutting performance.

11. Customizable stacking stations simplify the stacking of complex parts and make it easy to meet further production demands.

12. Optimized electrical cabinet design simplifies machine assembly and wiring installation process.

|

Mode |

fsct1100/850-2 |

fsct1100/850-3 |

fsct1100/850-4 |

|

Number of Sites |

2 |

3 |

4 |

|

Plate |

PPPS, PET, PVC, HIPS, PLA.OPS, EPS, C-PET, C-PLA, ABS |

||

|

Forming clamping force |

1050KN kN |

||

|

Punching clamping force |

1050KN kN |

||

|

Maximum molding area |

1100x850mm |

||

|

Maximum positive/negative depth |

145/125 |

||

|

Max. sheet width |

1130mm |

||

|

Maximum coil diameter |

1000mm,1.5 tons |

||

|

Sheet thickness range |

0.15-2 mm |

||

|

Maximum no-load speed |

55 Cycle time |

||

|

Air consumption |

6m/min,0.6-0.8Mpa |

||

|

Rated power |

290kv |

305kv |

320kv |

|

Dimensions (LxWxH) |

14000x2950x3500mm |

15500x2950x3500mm |

17500x2950x3500mm |

|

Weight |

17T |

25 tons |

33 tons |

GET A QUOTE