In the modern manufacturing industry, the production of plastic cups has become highly efficient and automated, thanks to a variety of specialized machines. These machines play a crucial role in transforming raw plastic materials into the cups we use daily for various purposes.

Thermoforming Machines

Thermoforming is a widely adopted technology in plastic cup production. Thermoforming machines work by heating plastic sheets until they become pliable. Once in a malleable state, the heated plastic is then stretched and formed into the desired cup shape, often using vacuum or pressure forming techniques. After the cups are formed, the excess plastic is trimmed away to give them a clean and finished look. These machines are highly versatile and can handle different types of plastics, such as polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and polyethylene terephthalate (PET). For example, PP is favored for its lightweight, heat-resistant, and recyclable properties, making it suitable for applications like hot beverage cups. The versatility of thermoforming machines allows manufacturers to produce a diverse range of cup styles and sizes to meet different market demands.

Injection Molding Machines

Another popular type of machine for making plastic cups is the injection molding machine. These machines operate by injecting molten plastic into a mold. The high - pressure injection ensures that the plastic fills every detail of the mold cavity precisely, resulting in high - precision cups with consistent quality. Injection molding is particularly well - suited for producing cups that require a high level of accuracy, such as those with intricate designs or specific wall - thickness requirements. However, compared to thermoforming machines, injection molding machines are generally more expensive. This is due to their complex mechanical and hydraulic systems, as well as the cost of the molds, which are often custom - made for each cup design.

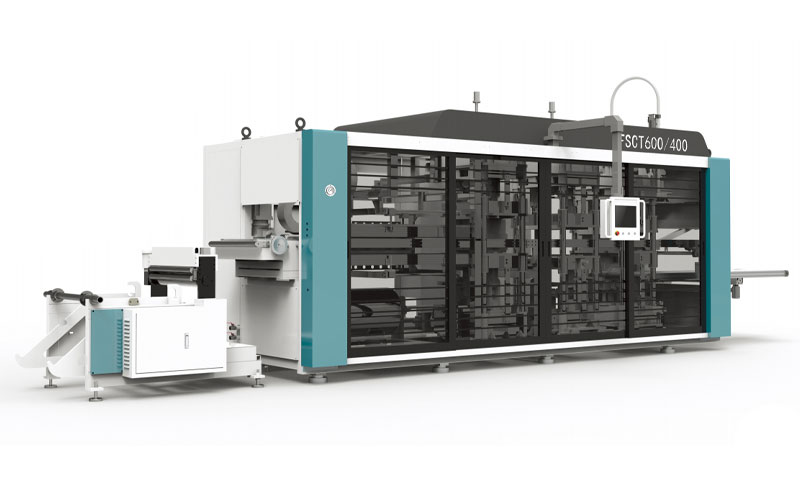

Automatic and Fully Automatic Machines

Plastic cup - making machines can be categorized as automatic or fully automatic. Automatic machines still require some level of human intervention. For instance, an operator may need to load plastic sheets into the machine at the beginning of the production cycle or remove the finished cups from the machine after they are formed. On the other hand, fully automatic machines have revolutionized the plastic cup production process. They can handle the entire production process from start to finish without much human assistance. This includes tasks such as automatically loading the plastic material, heating it, forming the cups, trimming the excess plastic, and even stacking the finished cups for easy packing and transportation. Fully automatic machines significantly reduce labor costs and increase production efficiency, making them an ideal choice for large - scale manufacturers who need to produce a high volume of plastic cups.

Additional Machines in the Production Line

In addition to the cup - forming machines, there are other machines involved in the complete plastic cup production process. For example, plastic cup 封口机 (plastic cup sealing machines) are used to seal plastic cups with plastic composite films or aluminum - plastic composite films. These machines perform automatic heat - sealing and automatic edge - cutting operations. After sealing, the packaged products not only have an aesthetically pleasing appearance but also a strong three - dimensional effect. They are designed to be user - friendly, with a simple and reasonable structure, making them easy to operate. Some advanced plastic cup sealing machines can also perform functions such as quantitative filling, using photoelectric positioning controllers to accurately determine the sealing position, which ensures accurate operation and high production efficiency.

In conclusion, the production of plastic cups relies on a combination of different machines, each with its own unique function and advantages. Thermoforming machines and injection molding machines are the main workhorses for shaping the cups, while automatic and fully automatic machines offer different levels of automation to meet various production needs. Additionally, machines like plastic cup sealing machines play an important role in the post - production process. Understanding these machines is essential for anyone interested in the plastic cup manufacturing industry, whether it's a small - scale business looking to enter the market or a large - scale manufacturer aiming to optimize production efficiency.