Thermoforming is a widely used manufacturing process that transforms plastic sheets into functional products by heating, shaping, and trimming them. Among the various types of thermoforming equipment, multi-station thermoforming machines have emerged as a game-changer for industries requiring high-volume production, precision, and versatility. This article dives into the main functions, benefits, and applications of multi-station thermoforming machines, explaining why they are a must-have for modern manufacturing.

What is a Multi Station Thermoforming Machine?

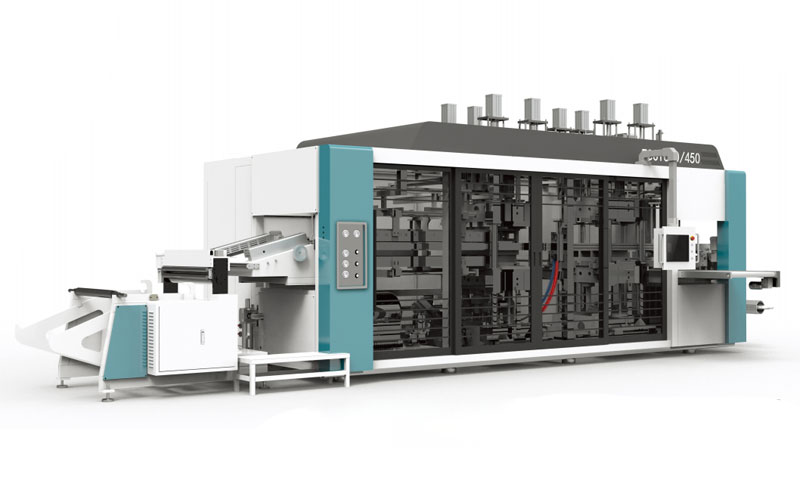

A multi station thermoforming machine is an advanced, automated system designed to streamline the thermoforming process by dividing it into multiple stages or "stations." Unlike single-station machines, which perform all steps in one location, multi-station machines allow for simultaneous operations, drastically improving production speed and consistency.

Each station is dedicated to a specific task, such as heating, forming, cooling, trimming, or stacking. The plastic sheet moves through these stations in a sequential manner, ensuring precision at every step. This modular approach not only boosts efficiency but also provides flexibility to handle diverse materials and complex product designs.

Key Functions of Multi-Station Thermoforming Machines

The primary function of a multi-station thermoforming machine is to automate and optimize the thermoforming process for high-volume production. Here’s a breakdown of its core functions:

1.Heating the Plastic Sheet

The first station heats the plastic sheet to its forming temperature using advanced heating systems like infrared or ceramic heaters. Uniform heat distribution is critical to ensure consistent product quality.

2.Forming the Product

Once heated, the plastic sheet moves to the forming station, where it is shaped using a custom mold. Multi-station machines excel at producing everything from simple trays to intricate automotive components with high precision.

3.Cooling and Solidification

After forming, the product is transferred to a cooling station, where fans or water-cooling systems rapidly cool and solidify the plastic. This step ensures dimensional accuracy and reduces cycle times.

4.Trimming and Finishing

The trimming station removes excess material and adds finishing touches. Automated tools ensure clean edges and precise dimensions, while additional stations can handle tasks like drilling holes or applying labels.

5.Stacking and Packaging

Some machines include stations for stacking and packaging finished products, reducing the need for manual labor and ensuring products are ready for shipment.

Why Choose Multi Station Thermoforming Machines?

Multi-station thermoforming machines offer several advantages that make them a top choice for manufacturers:

1.Faster Production Speeds

By performing multiple tasks simultaneously, these machines significantly reduce cycle times, making them ideal for high-volume production.

2.Superior Precision and Consistency

Dedicated stations ensure each step is executed with precision, resulting in consistent, high-quality products.

3.Versatility Across Materials and Designs

These machines can handle a wide range of materials, including PET, PVC, PP, and PS, as well as complex product designs.

4.Reduced Labor Costs

Automation minimizes manual intervention, lowering labor costs and reducing the risk of human error.

5.Scalability for Growing Businesses

Multi-station machines can be customized to meet specific production needs, allowing businesses to scale operations efficiently.

Applications of Multi Station Thermoforming Machines

Multi-station thermoforming machines are used across a variety of industries, including:

Food Packaging: Producing trays, containers, and clamshells for fresh and frozen foods.

Medical and Pharmaceutical: Manufacturing sterile packaging, blister packs, and surgical trays.

Automotive: Creating interior components, dashboards, and protective covers.

Consumer Goods: Producing items like toys, electronics housings, and cosmetic packaging.

Conclusion: The Future of Manufacturing is Here

Multi station thermoforming machines are revolutionizing the manufacturing landscape by combining speed, precision, and versatility. Their ability to automate complex processes and deliver consistent, high-quality products makes them indispensable for industries looking to stay competitive in today’s fast-paced market.

If you’re ready to boost your production efficiency and reduce operational costs, investing in a multi-station thermoforming machine is the smart choice. Contact us today to learn more about how this advanced technology can transform your manufacturing process!

Call to Action:

Looking for a reliable multi-station thermoforming machine? Contact us now to explore our cutting-edge solutions and take your production to the next level!